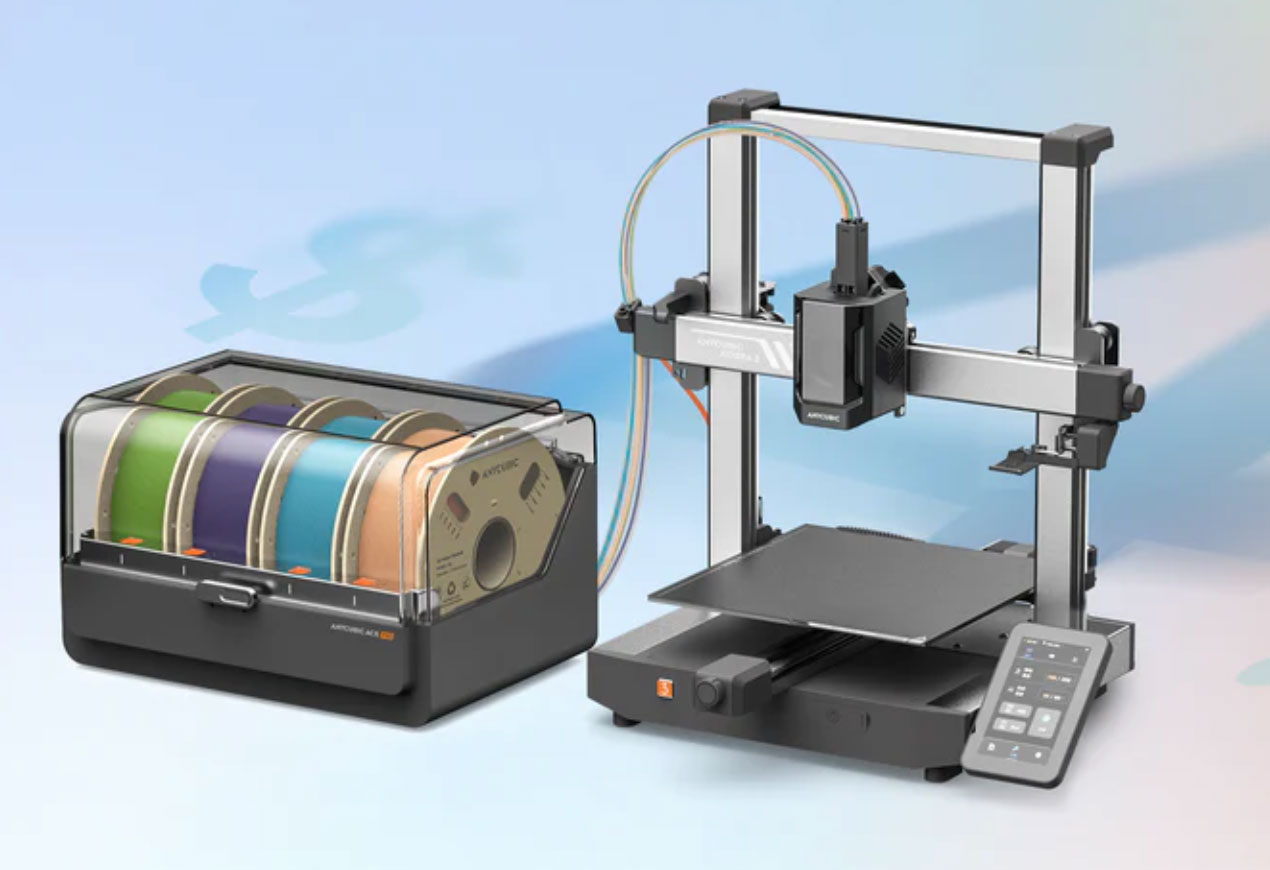

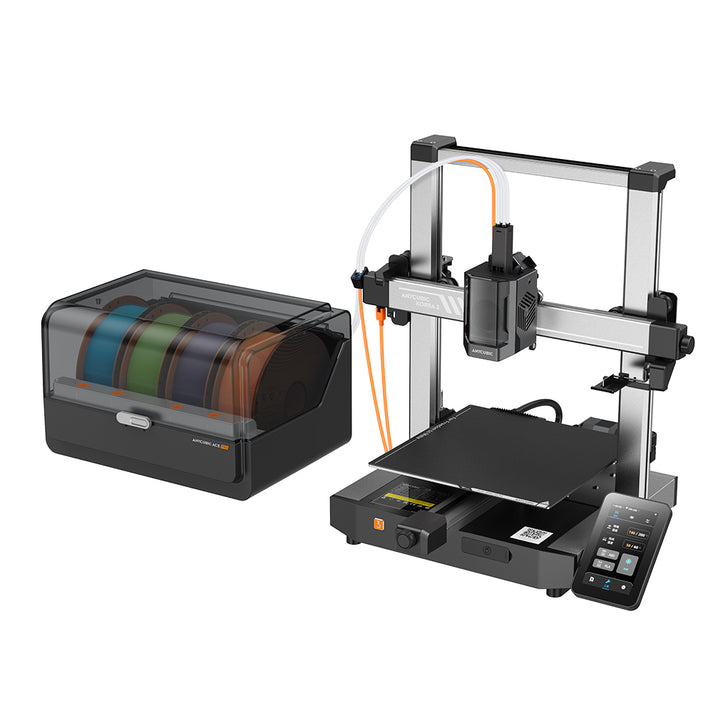

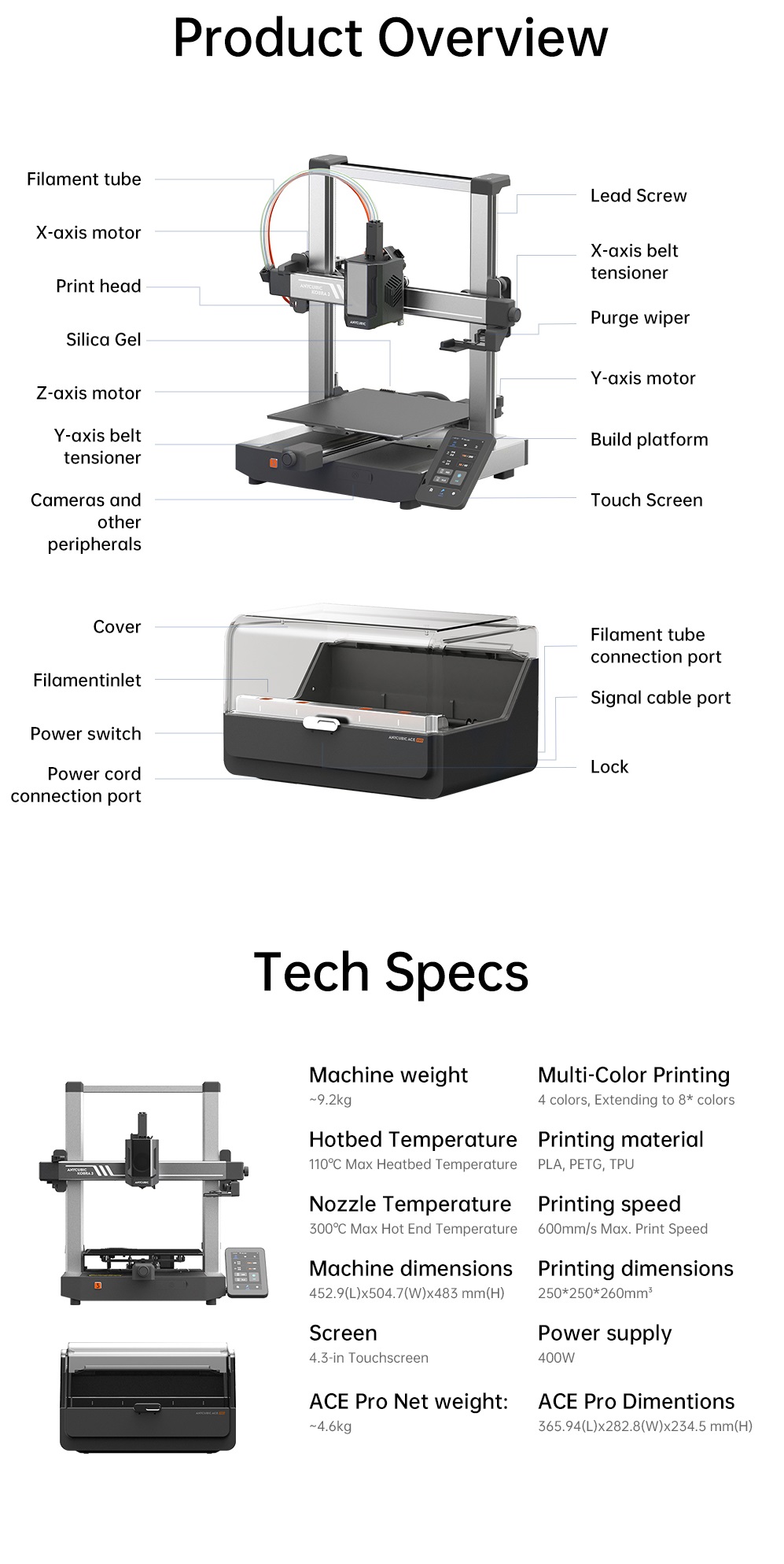

3D printing has revolutionized the way we create and innovate, and the Anycubic Kobra 3 Combo is a powerful tool that offers an immersive printing experience. This guide aims to provide you with essential tips and tricks to make the most of your Anycubic Kobra 3 Combo, ensuring optimal printing results and an enjoyable 3D printing journey.

Preparing for Printing

Before diving into the world of 3D printing with your Anycubic Kobra 3 Combo, there are a few crucial steps to take to ensure a smooth and successful printing process.

Choosing the Right Filament

The choice of filament greatly impacts the quality and success of your prints. Here are some tips for selecting the perfect filament:

- Consider Material Type: Anycubic Kobra 3 Combo supports a wide range of materials, including PLA, ABS, PETG, and more. Choose a filament that suits your project's requirements, considering factors like strength, flexibility, and temperature resistance.

- Check Filament Diameter: Ensure the filament diameter matches your printer's specifications. The Anycubic Kobra 3 Combo typically works with 1.75mm filaments, but always double-check to avoid any compatibility issues.

- Opt for High-Quality Brands: Investing in reputable filament brands ensures consistent printing results. Look for filaments with minimal moisture absorption and uniform diameter to avoid clogs and printing errors.

Preparing the Build Plate

A well-prepared build plate is crucial for successful prints. Follow these steps to ensure optimal adhesion and minimize warping:

- Clean the Build Plate: Before each print, clean the build plate with a mild detergent and water. Ensure it's completely dry to avoid any residue that might affect adhesion.

- Apply Adhesion Materials: Depending on the filament type, you can use adhesives like hairspray, PVA glue, or 3D printing bed adhesives. Apply a thin, even layer to the build plate to enhance adhesion.

- Level the Bed: Proper bed leveling is essential for accurate prints. Use the built-in bed leveling feature on the Anycubic Kobra 3 Combo to ensure the bed is perfectly flat and parallel to the nozzle.

Slicing Settings

Slicing your 3D models is a critical step in preparing them for printing. Here are some slicing settings to consider:

- Infill Density: Adjust the infill density based on the strength and aesthetics required for your print. Higher infill percentages result in stronger prints but use more filament.

- Layer Height: Choose an appropriate layer height for your desired print quality. Lower layer heights produce smoother surfaces but take longer to print.

- Support Settings: Enable support structures for overhangs and complex geometries. Ensure the support settings are optimized to avoid excessive support material and easy removal.

Printing Techniques

Now that your Anycubic Kobra 3 Combo is ready, let's explore some advanced printing techniques to elevate your 3D printing game.

Dual Extrusion

The Anycubic Kobra 3 Combo boasts dual extrusion capabilities, allowing you to print with two different materials or colors simultaneously. Here's how to make the most of this feature:

- Material Selection: Choose complementary materials or colors to create visually appealing and functional prints. For example, use a flexible material for the main structure and a rigid material for specific parts.

- Support Material: When using dual extrusion, consider the support material's properties. Some support materials are designed to be easily removable, ensuring a clean finish on your final print.

- Test Prints: Before starting a complex dual extrusion project, perform test prints to fine-tune the settings and ensure smooth material transitions.

Temperature Control

Temperature plays a vital role in 3D printing. Here are some tips for optimizing temperature settings:

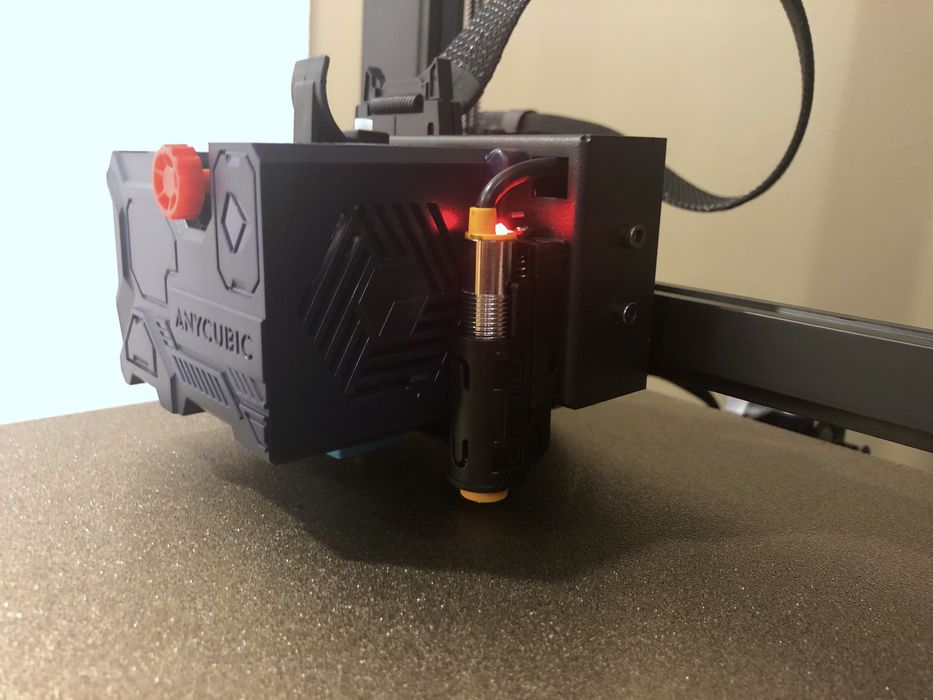

- Nozzle Temperature: Adjust the nozzle temperature based on the filament type. Different materials have specific melting points, so refer to the filament manufacturer's recommendations for optimal temperatures.

- Bed Temperature: The bed temperature affects adhesion and warping. Experiment with different temperatures to find the sweet spot for your chosen filament and build plate adhesion material.

- Temperature Control during Printing: Some filaments, like ABS, benefit from a controlled environment. Consider using an enclosure to maintain a consistent temperature during printing, reducing the risk of warping.

Advanced Features

The Anycubic Kobra 3 Combo offers several advanced features to enhance your printing experience. Here's a glimpse of what you can explore:

- Resume Printing: In case of power outages or interruptions, the Anycubic Kobra 3 Combo can resume printing from where it left off, ensuring you don't have to start over.

- Filament Run-Out Detection: This feature automatically pauses the print when the filament runs out, preventing potential jams and allowing for a quick filament change.

- Touchscreen Interface: The intuitive touchscreen interface makes it easy to navigate and control your printer, offering a seamless and user-friendly experience.

Troubleshooting and Maintenance

While 3D printing is an exciting process, occasional issues may arise. Here are some troubleshooting tips and maintenance practices to keep your Anycubic Kobra 3 Combo in top shape.

Common Printing Issues

Here are some common printing issues and their potential solutions:

- Clogged Nozzle: If you notice inconsistent filament flow or poor print quality, a clogged nozzle might be the culprit. Remove the nozzle and clean it with a nozzle cleaning kit or a specialized cleaning filament.

- Warping: Warping occurs when the edges of your print lift or curl. To minimize warping, ensure proper bed leveling, use a heated bed, and consider using a brim or raft for better adhesion.

- Layer Shifting: Layer shifting can result in misaligned layers and poor print quality. Check the belt tension and ensure the X and Y axes are properly calibrated to prevent this issue.

Regular Maintenance

Regular maintenance is key to keeping your Anycubic Kobra 3 Combo in optimal condition. Here are some maintenance practices to follow:

- Clean the Printer: Regularly clean the printer's exterior and interior to remove dust and debris. Pay attention to the build plate, nozzle, and extruder, ensuring they are free from residue.

- Lubricate Moving Parts: Lubricate the X, Y, and Z-axis lead screws and belts to ensure smooth movement and reduce friction. Use a high-quality, printer-specific lubricant to avoid any compatibility issues.

- Calibrate the Printer: Periodically calibrate your printer to maintain accuracy. Check the bed leveling, nozzle height, and axis calibration to ensure consistent and precise prints.

Conclusion

The Anycubic Kobra 3 Combo is a powerful 3D printing solution, offering a wide range of features and capabilities. By following the tips and techniques outlined in this guide, you can unlock the full potential of your printer and create stunning, high-quality prints. Remember to choose the right filament, prepare your build plate, and optimize your slicing settings for the best results. With practice and experimentation, you'll master the art of 3D printing and create innovative designs with ease.

FAQ

Can I use any filament with the Anycubic Kobra 3 Combo?

+

The Anycubic Kobra 3 Combo is compatible with a wide range of filament types, including PLA, ABS, PETG, and more. However, it’s important to choose high-quality filaments from reputable brands to ensure consistent printing results.

How do I prevent warping during printing?

+

To minimize warping, ensure proper bed leveling, use a heated bed, and consider applying a bed adhesion material like hairspray or PVA glue. Additionally, printing with a brim or raft can provide better adhesion and reduce the risk of warping.

What temperature settings should I use for different filaments?

+Temperature settings vary depending on the filament type. Refer to the filament manufacturer’s recommendations for optimal nozzle and bed temperatures. Generally, PLA requires lower temperatures, while materials like ABS and PETG may require higher temperatures for proper extrusion.

How can I achieve smoother print surfaces?

+To achieve smoother print surfaces, consider using a lower layer height, such as 0.1mm or 0.05mm. Additionally, post-processing techniques like sanding, priming, and painting can further enhance the surface finish of your prints.

Can I print with multiple materials simultaneously on the Anycubic Kobra 3 Combo?

+Yes, the Anycubic Kobra 3 Combo supports dual extrusion, allowing you to print with two different materials or colors simultaneously. This feature opens up endless possibilities for creating intricate and colorful designs.