For those interested in pursuing a career in welding, there are various entry-level positions available that offer an exciting and rewarding path into the industry. These jobs provide an opportunity to develop essential skills, gain valuable experience, and establish a solid foundation for future growth. In this blog post, we will explore the world of entry-level welding jobs, discussing the roles, responsibilities, and requirements associated with them. Whether you are a recent graduate or considering a career change, this guide will help you understand the opportunities that await in the welding industry.

Understanding Entry-Level Welding Jobs

Entry-level welding jobs are typically those that require minimal prior experience or training in welding. These positions are ideal for individuals who are new to the field and seeking to build their welding skills and knowledge. While some entry-level jobs may not require any formal welding certification, possessing basic welding skills and a willingness to learn can greatly enhance your chances of securing employment.

The welding industry offers a wide range of entry-level positions, each with its own set of responsibilities and requirements. Let's delve into some of the most common entry-level welding jobs and explore what they entail.

Welder Helper

A welder helper, also known as a welding assistant or welding apprentice, plays a crucial role in supporting the welding process. This entry-level position involves assisting experienced welders in various tasks, providing an excellent opportunity to learn the trade and gain hands-on experience.

Key Responsibilities

- Assisting welders in setting up and preparing workpieces for welding.

- Cleaning and preparing surfaces to ensure proper adhesion.

- Cutting and shaping materials using hand tools or power tools.

- Assisting with the positioning and clamping of workpieces.

- Helping with the maintenance and organization of welding equipment.

- Performing basic welding tasks under the supervision of experienced welders.

Requirements

- No formal welding certification is typically required for this position.

- Basic knowledge of welding processes and safety procedures is beneficial.

- Physical strength and the ability to lift heavy objects are essential.

- Attention to detail and a willingness to learn are crucial.

- Excellent communication and teamwork skills are necessary for effective collaboration with welders.

Fabricator

Fabricators are responsible for creating and assembling metal structures and components. This entry-level position involves working with various materials and utilizing different fabrication techniques to produce high-quality products.

Key Responsibilities

- Reading and interpreting blueprints, drawings, and specifications.

- Cutting, shaping, and bending metal materials using power tools and machinery.

- Welding components together to create structures or assemblies.

- Assembling and fitting parts according to specified dimensions and tolerances.

- Performing quality control checks and ensuring accuracy in fabrication.

- Maintaining a clean and organized work area.

Requirements

- A high school diploma or equivalent is typically required.

- Basic knowledge of welding processes and metal fabrication techniques is beneficial.

- Proficiency in using hand tools and power tools is essential.

- Good understanding of measurements and attention to detail.

- Physical stamina and the ability to work in a fast-paced environment.

Welding Technician

Welding technicians play a vital role in ensuring the quality and accuracy of welding processes. This entry-level position involves working closely with welders and engineers to set up, monitor, and maintain welding equipment and procedures.

Key Responsibilities

- Assisting in the setup and calibration of welding equipment.

- Conducting quality control inspections and tests on welded joints.

- Collecting and analyzing data related to welding processes.

- Troubleshooting and resolving welding-related issues.

- Maintaining accurate records and documentation.

- Collaborating with welders and engineers to optimize welding techniques.

Requirements

- A high school diploma or equivalent is typically required.

- Basic knowledge of welding processes and quality control procedures.

- Proficiency in using welding equipment and tools.

- Strong attention to detail and analytical skills.

- Good communication and problem-solving abilities.

Welding Inspector

Welding inspectors are responsible for evaluating the quality and integrity of welded joints and structures. This entry-level position requires a keen eye for detail and a thorough understanding of welding standards and specifications.

Key Responsibilities

- Inspecting welded joints and structures for defects and discrepancies.

- Conducting non-destructive testing (NDT) methods such as ultrasonic testing, radiographic testing, or magnetic particle testing.

- Documenting inspection results and preparing detailed reports.

- Identifying non-conformances and recommending corrective actions.

- Ensuring compliance with industry standards and regulations.

- Collaborating with welders and engineers to improve welding practices.

Requirements

- A high school diploma or equivalent is typically required.

- Basic knowledge of welding processes and inspection techniques.

- Proficiency in using inspection tools and equipment.

- Excellent attention to detail and observational skills.

- Good communication and reporting abilities.

Welding Apprentice

A welding apprentice is an individual who is undergoing training and gaining practical experience in the welding field. This entry-level position provides an opportunity to learn from experienced welders and develop a strong foundation in welding techniques and practices.

Key Responsibilities

- Assisting welders in various tasks and learning welding techniques.

- Practicing welding skills under the guidance of experienced welders.

- Attending training sessions and workshops to enhance welding knowledge.

- Completing assigned projects and tasks to gain hands-on experience.

- Maintaining a safe and organized work environment.

Requirements

- A high school diploma or equivalent is typically required.

- Enthusiasm and a strong desire to learn welding skills.

- Physical fitness and the ability to work in a physically demanding environment.

- Willingness to follow instructions and learn from experienced welders.

- Basic knowledge of welding safety procedures.

Skills and Qualifications for Entry-Level Welding Jobs

While specific requirements may vary depending on the job and employer, there are certain skills and qualifications that are highly valued in the welding industry for entry-level positions. Here are some key skills and qualifications to consider:

- Basic Welding Skills: Having a fundamental understanding of welding processes, such as arc welding, gas welding, or TIG welding, is advantageous. Familiarity with different welding techniques and the ability to produce quality welds are essential.

- Safety Awareness: Welding involves working with hot materials and potentially hazardous conditions. A strong commitment to safety, knowledge of safety protocols, and the ability to identify and mitigate risks are crucial.

- Attention to Detail: Welding requires precision and accuracy. Entry-level welders should possess excellent attention to detail to ensure the quality and integrity of their work.

- Physical Stamina: Welding can be physically demanding, often requiring long periods of standing, lifting heavy objects, and working in awkward positions. Good physical fitness and endurance are essential.

- Technical Skills: Proficiency in using hand tools, power tools, and welding equipment is vital. Entry-level welders should be comfortable operating various machinery and have a basic understanding of metal fabrication techniques.

- Communication Skills: Effective communication is essential for collaboration with colleagues, supervisors, and clients. Clear and concise communication ensures that instructions are understood and work is completed accurately.

- Problem-Solving Abilities: Welding often presents unique challenges and problems that require creative solutions. Entry-level welders should possess critical thinking skills and the ability to troubleshoot and find effective solutions.

- Willingness to Learn: The welding industry is constantly evolving, with new techniques and technologies emerging. Entry-level welders should demonstrate a strong desire to learn, adapt, and stay updated with industry advancements.

Training and Education for Entry-Level Welders

While some entry-level welding jobs may not require formal education or certification, investing in training and education can greatly enhance your skills and employment prospects. Here are some training options to consider:

- Vocational Schools: Vocational schools offer welding programs that provide hands-on training and instruction in various welding techniques. These programs typically last a few months to a year and can lead to certification or a welding diploma.

- Community Colleges: Many community colleges offer welding programs or courses as part of their curriculum. These programs often combine classroom instruction with practical training, providing a well-rounded education in welding.

- Apprenticeship Programs: Apprenticeship programs provide on-the-job training and mentorship under the guidance of experienced welders. These programs typically last several years and offer a combination of classroom instruction and hands-on work experience.

- Online Courses: Online platforms offer a wide range of welding courses and tutorials that can help you develop basic welding skills and knowledge. While online courses may not provide the same level of hands-on experience, they can be a valuable supplement to traditional training.

🚨 Note: It is important to research and choose accredited training programs or institutions to ensure the quality and recognition of your welding education.

Tips for Securing Entry-Level Welding Jobs

Securing an entry-level welding job can be competitive, but with the right approach and preparation, you can increase your chances of success. Here are some tips to help you stand out and land your dream welding job:

- Build a Strong Resume: Highlight your welding skills, relevant experience, and any certifications or training you have completed. Include any projects or assignments that demonstrate your practical welding abilities.

- Create a Professional Portfolio

- Compile a collection of your best welding work, including photos or videos of your completed projects. A portfolio showcases your skills and can be a powerful tool to impress potential employers.

- Network and Attend Industry Events: Attend welding-related conferences, seminars, or trade shows to connect with industry professionals. Networking can open doors to job opportunities and provide valuable insights into the welding industry.

- Seek Mentorship: Reach out to experienced welders or professionals in the industry who can offer guidance and support. Mentors can provide valuable advice, share their knowledge, and help you navigate the job market.

- Stay Updated with Industry Trends: Keep yourself informed about the latest welding technologies, techniques, and advancements. Stay active in welding communities, join online forums, and follow welding-related publications to stay up-to-date.

- Be Prepared for Interviews: Research the company and the position you are applying for. Prepare answers to common interview questions and be ready to showcase your welding skills and knowledge. Practice your interview skills to boost your confidence.

Conclusion

Entry-level welding jobs provide an excellent gateway into the welding industry, offering a range of opportunities for individuals to develop their skills and advance their careers. Whether you aspire to become a welder, fabricator, welding technician, or inspector, there are numerous paths to explore. By understanding the different entry-level positions, acquiring the necessary skills and qualifications, and investing in training and education, you can embark on a rewarding journey in the welding industry. Remember, welding is a skilled trade that requires dedication, precision, and a passion for craftsmanship. So, roll up your sleeves, ignite your welding torch, and embark on an exciting career path in the world of welding!

Frequently Asked Questions

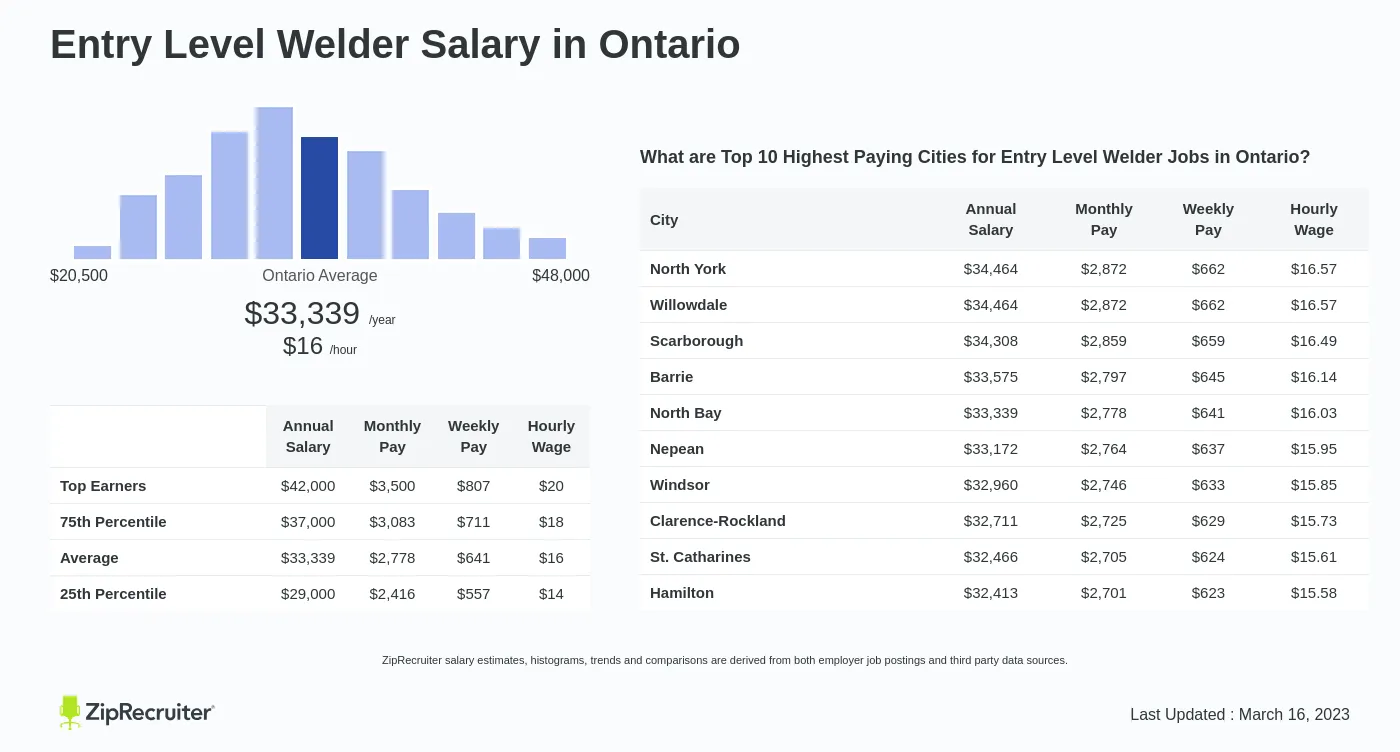

What are the average salaries for entry-level welding jobs?

+Salaries for entry-level welding jobs can vary depending on factors such as location, industry, and experience. On average, welder helpers and apprentices can expect to earn around 15 to 20 per hour. Fabricators and welding technicians may earn slightly higher, with average salaries ranging from 18 to 25 per hour. Welding inspectors typically have higher salaries, with an average range of 25 to 35 per hour.

Are there any age restrictions for entry-level welding jobs?

+Age restrictions for entry-level welding jobs vary depending on the employer and local regulations. While there may be no explicit age restrictions, some employers may prefer candidates who are physically fit and able to perform the physically demanding tasks associated with welding. It is important to check the specific requirements of each job posting.

Can I work my way up to a higher-level welding position without formal education?

+Absolutely! While formal education can provide a strong foundation, many welders have successfully advanced their careers through on-the-job training, apprenticeships, and continuous learning. By demonstrating your skills, dedication, and willingness to learn, you can progress to higher-level welding positions without a formal degree.

What are the career prospects for entry-level welders?

+The welding industry offers excellent career prospects for entry-level welders. With experience and additional training, you can advance to more specialized roles such as certified welder, welding supervisor, or welding engineer. Additionally, welders can explore various industries, including construction, manufacturing, aerospace, and automotive, opening up a wide range of career opportunities.

Are there any health and safety concerns associated with welding jobs?

+Welding jobs involve working with hot materials, intense light, and potentially hazardous substances. It is important to prioritize health and safety by following proper safety protocols, wearing appropriate personal protective equipment (PPE), and being aware of potential hazards. Regular training and staying updated with safety regulations are essential to minimize risks.