Melting gold is a process that involves carefully heating the metal to reach its melting point, allowing it to transform from a solid to a liquid state. This process is crucial in various industries, including jewelry making, electronics, and even dentistry. Understanding the proper techniques and safety measures is essential when working with molten gold, as it requires precision and control to achieve the desired results.

Understanding Gold’s Melting Point

Gold, known for its remarkable properties, has a relatively high melting point compared to other metals. The melting point of gold varies depending on its purity and the presence of any impurities or alloys. Pure gold, also known as 24-karat gold, has a melting point of approximately 1064.43 °C (1947.97 °F). This temperature is crucial to consider when planning the melting process, as it ensures the metal is heated to the right temperature for a successful melt.

Safety Precautions for Melting Gold

Working with molten gold requires strict adherence to safety protocols to prevent accidents and injuries. Here are some essential safety measures to consider:

- Personal Protective Equipment (PPE): Wear appropriate PPE, including heat-resistant gloves, a face shield, and a laboratory coat or apron to protect your skin and eyes from hot metal and potential splashes.

- Ventilation: Ensure proper ventilation in the workspace to prevent the buildup of harmful fumes. Gold, when heated, can release toxic gases, so having a well-ventilated area is crucial.

- Fire Safety: Keep a fire extinguisher nearby and be familiar with its use. Additionally, have a fire blanket readily available to smother any potential fires.

- Heating Equipment: Use a dedicated melting furnace designed for gold and other precious metals. These furnaces are specifically engineered to control temperature and prevent accidental overheating.

- Cooling Area: Prepare a designated cooling area for the molten gold to prevent any accidental contact with flammable or heat-sensitive materials.

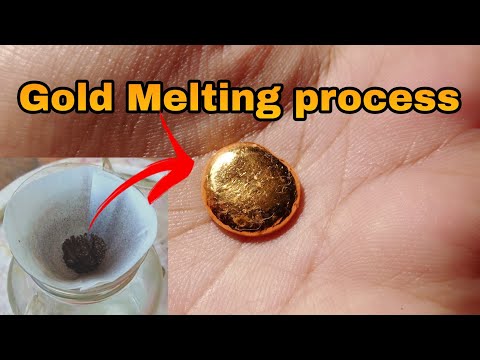

The Melting Process

Melting gold is a precise process that requires careful attention to detail. Here’s a step-by-step guide to melting gold safely and effectively:

- Prepare the Gold: Start by cleaning the gold thoroughly to remove any dirt, grease, or oxidation. Use a mild detergent and warm water, and ensure the gold is completely dry before proceeding.

- Weigh the Gold: Accurately weigh the gold to determine the required heat and time for melting. The weight will also help in calculating the gold's value after the melting process.

- Set Up the Melting Furnace: Preheat the melting furnace to the desired temperature, ensuring it reaches and maintains a consistent heat. Use a high-quality, calibrated thermometer to monitor the temperature.

- Place the Gold in the Crucible: Use a graphite or ceramic crucible specifically designed for melting gold. Place the cleaned and weighed gold into the crucible, ensuring it is centered and not touching the crucible's walls.

- Begin the Melting Process: Carefully lower the crucible into the preheated furnace, using heat-resistant gloves and tongs. Keep a safe distance from the furnace to avoid burns.

- Monitor the Melting Process: Observe the gold closely as it begins to melt. The gold will first become soft and pliable, and then it will start to liquefy. Ensure the temperature remains consistent and does not exceed the melting point of gold.

- Pour the Molten Gold: Once the gold has completely melted, carefully remove the crucible from the furnace using heat-resistant gloves and tongs. Pour the molten gold into a suitable mold or casting equipment. Ensure the mold is preheated to prevent thermal shock.

- Cooling and Solidification: Allow the molten gold to cool and solidify in the mold. This process can take several minutes to an hour, depending on the size and shape of the mold. Do not disturb the gold during this critical cooling period.

- Post-Melting Cleaning: After the gold has solidified, carefully remove it from the mold and clean any residual mold material or impurities. Use a soft, clean cloth and a mild cleaning solution to avoid damaging the gold's surface.

Applications of Melted Gold

Melted gold has a wide range of applications across various industries. Here are some common uses:

- Jewelry Making: Melted gold is a crucial component in the creation of jewelry. It allows for the casting of intricate designs and the formation of various shapes and sizes, providing endless possibilities for jewelry designers.

- Electronics: Gold is an excellent conductor of electricity and is used in various electronic components, such as connectors, contacts, and printed circuit boards. Melting gold allows for the precise formation of these components, ensuring optimal electrical performance.

- Dental Work: Gold has been used in dentistry for centuries due to its biocompatibility and durability. Melted gold can be cast into dental crowns, bridges, and other restorative devices, providing long-lasting and aesthetically pleasing solutions.

- Art and Sculpture: Artists and sculptors often use melted gold to create unique and valuable artworks. The malleability of molten gold allows for the formation of intricate details and the addition of textures, resulting in stunning visual effects.

- Industrial Applications: Gold's excellent thermal and electrical conductivity, along with its corrosion resistance, makes it valuable in various industrial applications. Melted gold is used in the production of specialized coatings, connectors, and other high-performance components.

Common Challenges and Solutions

While melting gold is a fascinating process, it comes with its own set of challenges. Here are some common issues and their solutions:

Impurities and Alloys

Gold often contains impurities or is alloyed with other metals, which can affect its melting point and overall quality. To address this:

- Use a high-quality, pure gold source, such as 24-karat gold, to minimize impurities.

- If alloying is necessary, carefully control the composition and ensure the alloys are compatible with the melting process.

- Consider using a refining process before melting to remove impurities and improve the gold's purity.

Temperature Control

Maintaining a consistent and precise temperature is crucial during the melting process. To achieve this:

- Invest in a high-quality melting furnace with accurate temperature control and monitoring capabilities.

- Calibrate the furnace regularly to ensure its readings are accurate and reliable.

- Use a separate thermometer to cross-check the furnace's temperature readings and make adjustments as needed.

Thermal Shock

Thermal shock occurs when a material experiences a rapid change in temperature, leading to cracks or fractures. To prevent thermal shock during the melting and cooling process:

- Preheat the mold or casting equipment to a temperature close to the melting point of gold.

- Slowly cool the molten gold to allow for a gradual temperature change, reducing the risk of thermal shock.

- Use materials with similar thermal expansion coefficients to minimize stress during cooling.

Oxidation and Contamination

Gold can oxidize when exposed to high temperatures, leading to a loss of quality and value. To prevent oxidation and contamination:

- Work in a well-ventilated area to minimize the buildup of harmful gases.

- Use a protective atmosphere, such as an inert gas like argon, to prevent oxidation during the melting process.

- Clean the gold thoroughly before melting to remove any dirt or contaminants that could affect the melting process.

Environmental Considerations

The melting of gold, like any industrial process, has environmental implications. Here are some key considerations:

- Energy Consumption: Melting gold requires a significant amount of energy, so it's essential to use energy-efficient equipment and practices to minimize the environmental impact.

- Waste Management: Proper disposal of waste materials, such as impurities and alloys, is crucial to prevent environmental pollution. Ensure compliance with local regulations and best practices for waste management.

- Sustainable Sourcing: Consider the origin of the gold being melted. Opt for responsibly sourced gold to support ethical practices and minimize the environmental and social impacts of gold mining.

What is the melting point of gold?

+The melting point of pure gold, also known as 24-karat gold, is approximately 1064.43 °C (1947.97 °F). This temperature is crucial to consider when melting gold to ensure it is heated to the correct point for a successful melt.

What are the common applications of melted gold?

+Melted gold has a wide range of applications, including jewelry making, electronics, dental work, art and sculpture, and various industrial uses. Its unique properties, such as high conductivity and corrosion resistance, make it valuable in these industries.

What safety precautions should be taken when melting gold?

+When melting gold, it’s essential to wear personal protective equipment (PPE), ensure proper ventilation, have fire safety equipment readily available, use a dedicated melting furnace, and prepare a designated cooling area. These measures help prevent accidents and ensure a safe working environment.

How can I prevent impurities and alloys from affecting the melting process?

+To minimize the impact of impurities and alloys, use high-quality, pure gold sources, carefully control alloy compositions, and consider refining the gold before melting. These steps help ensure a smoother melting process and maintain the gold’s quality.