Unleashing Precision: Exploring the World of Milling Machines

In the realm of manufacturing and machining, milling machines stand as versatile and powerful tools, capable of shaping various materials with exceptional precision. This article delves into the intricacies of milling, offering an in-depth guide to understanding and utilizing these machines effectively.

The Fundamentals of Milling

Milling, at its core, is a machining process that employs rotating multipoint cutting tools to remove material from a workpiece. This method, in contrast to drilling, which uses single-point cutting tools, allows for the creation of complex shapes and surfaces with remarkable accuracy.

The milling process can be categorized into two main types: peripheral milling and face milling. Peripheral milling, also known as slab milling, involves the removal of material from the surface of the workpiece using the periphery of the milling cutter. Face milling, on the other hand, utilizes the face of the milling cutter to remove material from the workpiece, typically creating flat surfaces.

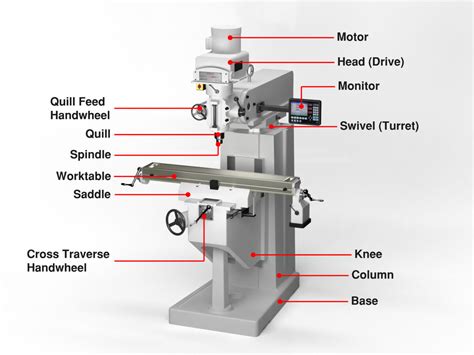

The Anatomy of a Milling Machine

A milling machine is a complex piece of equipment, designed to perform a range of milling operations with precision and efficiency. The key components of a milling machine include:

- Base: The foundation of the machine, providing stability and support.

- Knee: A vertical, adjustable casting that supports the saddle and table.

- Saddle: Mounted on the knee, it provides vertical movement for the table.

- Table: The surface on which the workpiece is clamped and positioned for milling.

- Overarm: Supports the milling head and allows for vertical and horizontal adjustment.

- Milling Head: Houses the spindle and the milling cutter, providing the cutting action.

- Spindle: The rotating component that holds and drives the milling cutter.

- Milling Cutter: The cutting tool, available in various shapes and sizes, responsible for material removal.

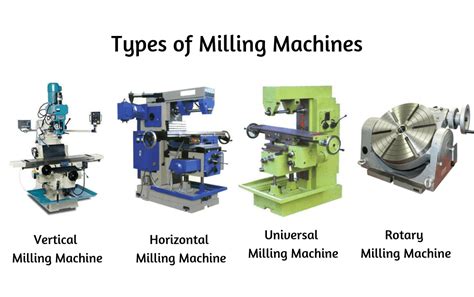

Types of Milling Machines

Milling machines come in various configurations, each designed for specific applications and levels of precision. The most common types include:

- Horizontal Milling Machine: Features a horizontal spindle orientation, making it suitable for heavy-duty cutting and large workpieces.

- Vertical Milling Machine: With a vertical spindle, these machines are ideal for precision milling and smaller workpieces.

- Universal Milling Machine: Versatile machines that can perform both horizontal and vertical milling operations.

- CNC Milling Machine: Computer Numerical Control machines, offering precise and automated milling operations.

Milling Operations and Techniques

Milling machines offer a wide range of operations, allowing for the creation of intricate shapes and surfaces. Some common milling operations include:

- Plain Milling: Also known as surface milling, this operation involves the use of a plain milling cutter to create flat surfaces.

- Angular Milling: Employs an angular milling cutter to create angles and grooves on the workpiece.

- Form Milling: Utilizes specially shaped milling cutters to create complex shapes and contours.

- End Milling: Involves the use of end mills to create slots, pockets, and profiles on the workpiece.

- Face Milling: As mentioned earlier, this operation uses the face of the milling cutter to create flat surfaces.

Selecting the Right Milling Cutter

The choice of milling cutter is crucial for achieving the desired milling outcome. Factors to consider when selecting a milling cutter include:

- Material: Choose a cutter made from a material suitable for the workpiece material, ensuring optimal cutting performance.

- Shape: Select a cutter shape that aligns with the desired milling operation, such as plain, face, or end mills.

- Size: Consider the size of the cutter, ensuring it fits within the milling machine and can effectively remove material.

- Flutes: The number of flutes on the cutter affects the chip load and cutting performance. More flutes provide a smoother finish but may reduce chip clearance.

Milling Machine Safety and Maintenance

Safety is paramount when operating milling machines. Always follow these safety guidelines:

- Wear appropriate personal protective equipment, including safety glasses, ear protection, and gloves.

- Ensure the workpiece is securely clamped to prevent movement during milling.

- Keep long hair and loose clothing away from the machine to avoid accidents.

- Regularly inspect the machine for any signs of wear or damage, and address issues promptly.

Maintenance is also crucial to ensure the longevity and performance of your milling machine. Key maintenance tasks include:

- Lubricating moving parts regularly to reduce friction and wear.

- Cleaning the machine after each use to prevent the buildup of chips and debris.

- Periodically checking and tightening all fasteners to maintain machine integrity.

- Calibrating and adjusting the machine as needed to ensure precision milling.

Advanced Milling Techniques

For those seeking to enhance their milling capabilities, several advanced techniques can be employed. These include:

- Climb Milling: A technique where the cutter moves in the same direction as the feed, resulting in a smoother finish and reduced tool wear.

- Conventional Milling: Opposite to climb milling, the cutter moves against the feed, providing better control over the workpiece.

- Helical Interpolation: A complex technique that involves the simultaneous rotation and movement of the cutter to create helical shapes.

- High-Speed Milling: Utilizing high spindle speeds and advanced cutter designs to achieve faster material removal rates.

Troubleshooting Common Milling Issues

While milling machines are precision instruments, issues can arise. Here are some common problems and their potential solutions:

| Problem | Solution |

|---|---|

| Excessive Vibration | Check for loose components, ensure proper tool selection, and maintain optimal cutting parameters. |

| Poor Surface Finish | Adjust feed rates, cutter speed, and depth of cut. Ensure proper tool sharpening and replace worn cutters. |

| Tool Breakage | Review cutting parameters, tool selection, and workpiece clamping. Consider the workpiece material's hardness and tool material compatibility. |

Conclusion

Milling machines are versatile and powerful tools, offering a range of capabilities for shaping materials with precision. By understanding the fundamentals of milling, selecting the right equipment and cutters, and employing proper techniques and maintenance, you can unlock the full potential of these machines. Whether you're a hobbyist or a professional machinist, mastering the art of milling opens up a world of creative possibilities.

What is the difference between peripheral and face milling?

+

Peripheral milling, or slab milling, uses the periphery of the milling cutter to remove material from the workpiece’s surface. Face milling, on the other hand, employs the face of the cutter to create flat surfaces.

How do I choose the right milling cutter for my project?

+

Consider the workpiece material, the desired milling operation, and the size and shape of the cutter. Select a cutter made from a suitable material, with the right number of flutes, and ensure it fits within your milling machine.

What are some safety precautions when using a milling machine?

+

Always wear appropriate PPE, secure the workpiece, and keep loose clothing and hair away from the machine. Regularly inspect the machine for wear and damage, and address any issues promptly.

How can I improve the surface finish of my milled parts?

+

Adjust feed rates, cutter speed, and depth of cut. Ensure proper tool sharpening and replace worn cutters. Consider using a finish pass with a finer cutter to achieve a smoother surface.